Georgia Tech Students Win ASME Hackathon

August 21, 2020

A massive amount of unstructured data is being produced every day, and making use of it in engineering settings is an ongoing challenge. That is why this year’s 2020 ASME-CIE Hackathon focused on identifying, extracting, and analyzing value from large unstructured data sets in mechanical engineering.

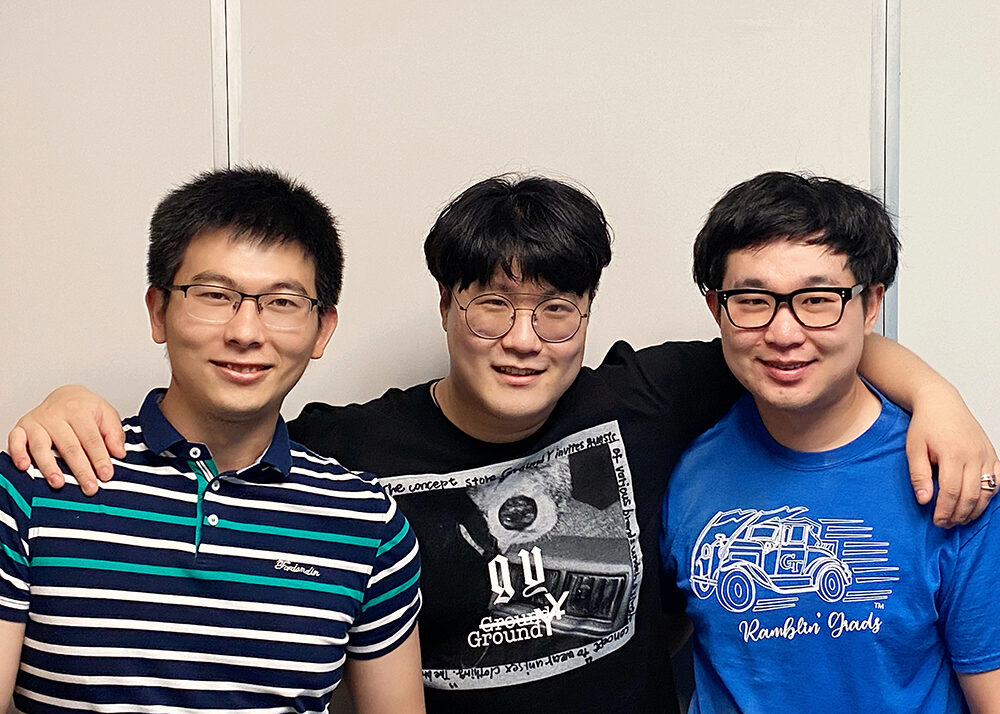

The 24-hour event ran from August 5 until August 16 and pushed participants to come up with a means for interpreting or predicting data in one of two scenarios. The victorious team was a trio of Georgia Tech graduate students consisting of mechanical engineering Ph.D. students Su Yu and Changxuan Zhao and computer science and engineering master’s student Muyang Guo. All three team members started their academic careers at Georgia Tech as mechanical engineering undergraduates.

In the span of 24 hours, with minimal sleep, they developed an ensemble machine learning model using a stacking technique and achieved the highest prediction accuracy of any team while solving a problem based on machine health diagnostics and monitoring. They were given historical data for equipment in an industrial setting, and based on past behavior they had to predict how the equipment would perform in the future.

“It’s very hard to create a good program with functional accuracy in that timeframe,” said Su Yu. “We had to estimate two different variables for five different machines, 10 variables total. That was the biggest challenge.”

In addition to the sheer number of variables, they also had to account for the order in which they happened, which was critical. To tackle these challenges the group pre-processed the data set, improving their accuracy. They also decided that each team member would build their own machine-learning model with its own strengths and then combine them. The final model was more robust than the models of their competitors and proved to be the most accurate.

Su Yu is excited about the possibility of their model being used in real world work environments.

“Let’s say a machine is currently run for eight hours per day, and a machine shop wants to increase capacity and run it for 24 hours a day,” he explained. “What is the risk of damage? Instead of running the equipment to find out, they could use our simulation, reducing risk and saving money.”

For their efforts, the Georgia Tech team earned $2,000 in prize money, and come away with a better understanding of the application of machine-learning techniques, and the confidence derived from knowing they are up for any challenge.

“Without challenges, I would never know my limits,” added Yu. “This hackathon is something I would recommend to anyone, and I will recommend it to people I know. In general, many engineers are not always taught a lot of coding skills, and this is a good way to sharpen your coding skills and combine it with machine learning algorithms to offer data driven solutions to engineering problems.”